WasteWater Treatment

To safeguard our water

Sufficient wastewater treatment is essential for preserving the health of water sources, safeguarding the quality of our drinking water, and facilitating direct water reuse. Technological progress is expanding the possibilities for wastewater treatment, and in response, municipalities are increasingly focusing on advanced technologies and processes to achieve higher levels of purification and protect water bodies. Resource recovery, such as energy, and sustainable reuse of treated wastewater are emphasized, providing alternative water sources for urban and agricultural irrigation, and industrial supply.

We provide our customers with comprehensive and future-proof wastewater management solutions.

WABAG offers state-of-the-art complete plants meticulously designed for these objectives. We deliver customized solutions tailored to diverse needs, covering carbon to nutrient removal and the elimination of micropollutants, utilizing our extensive range of conventional and innovative technologies.

The removal of micropollutants in wastewater has gained significant importance in recent years. As a pioneer in the field, WABAG has developed suitable processes and is one of the few companies capable of offering all the relevant technologies, including ozonation and activated carbon adsorption, as well as their combination. Over the past decade, WABAG has successfully implemented additional (4th) treatment stages in many plants.

Our expertise is backed by hundred years of industry experience having built numerous plants for wastewater treatment. Discover two examples of recently completed projects:

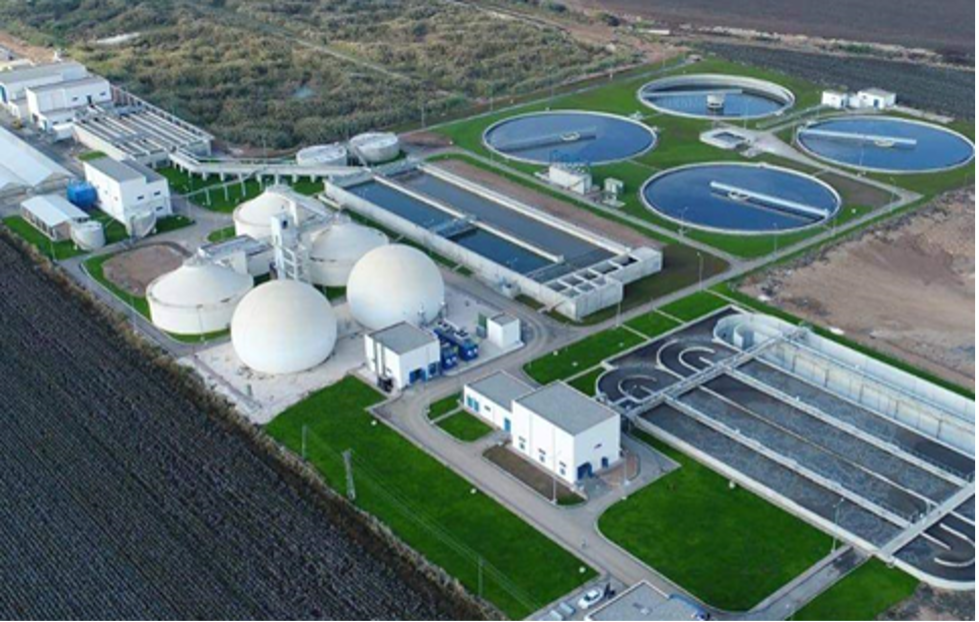

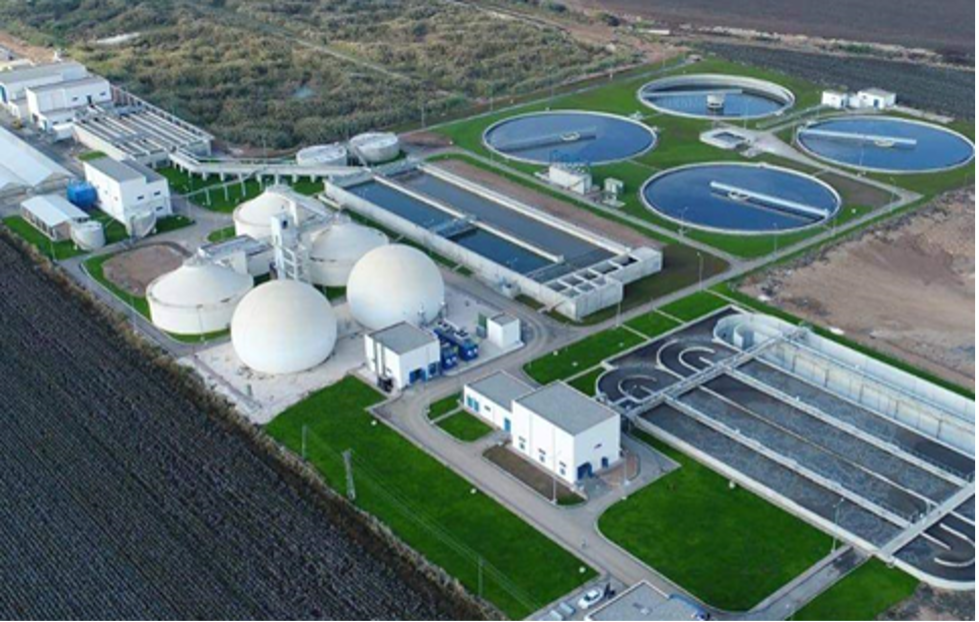

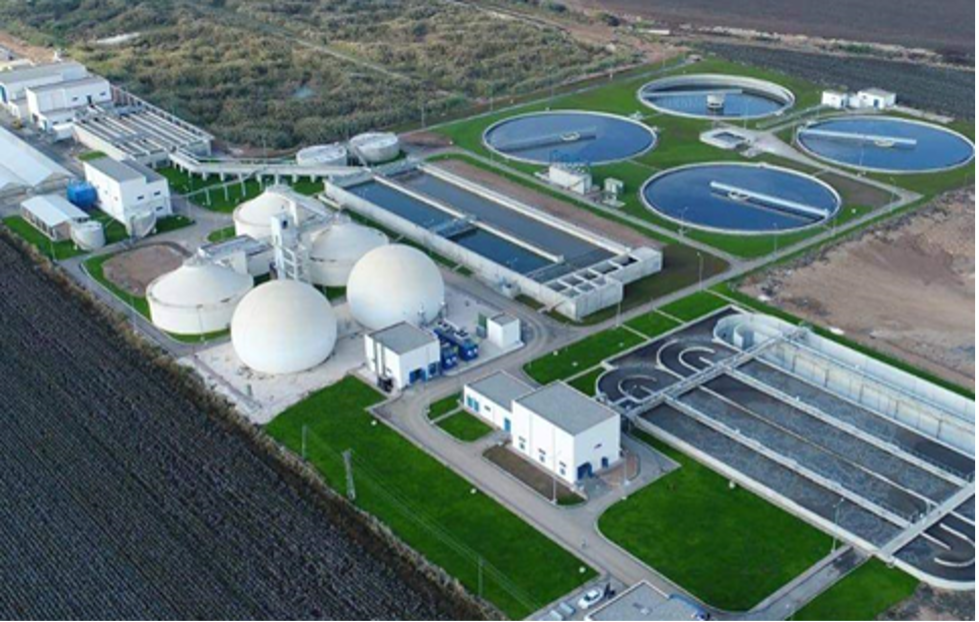

Jubail Industrial City, Saudi Arabia, 120 MLD

Wastewater treatment and Water Reuse plant supporting the sustainable Saudi Vision 030.

The industrial and port city of Jubail is located on the coast of the Arabian Gulf. It is the world’s largest single industrial development project custom-built over the last decade as a location for major industries. Alongside the industrial facilities, residential areas were also built and, in response to the strong influx into the industrial city, were also continuously expanded.

For the environmentally-friendly treatment and sustainable reuse of the treated wastewater WABAG has completed a state-of-the-art wastewater treatment (WWTP) and water reclamation plant. With a capacity of 120,000 m3/d, this WWTP stands as one of the largest wastewater infrastructures in the region, making a significant contribution to the sustainable goals of Saudi Vision 2030. One of their central targets is to ensure that water obtained through desalination is reused as a minimum requirement for irrigation.

The turnkey WWTP includes biological treatment as well as wastewater filtration and disinfection. This 3-stage treatment process ensures the treatment of municipal wastewater from Jubail town and its Industrial City to irrigation water quality standards set by the Royal Commission of Jubail. Treated and reclaimed water is distributed to the city’s irrigation system, keeping the city clean and green and promoting a safe, clean, and healthy environment for the city’s 700,000 inhabitants, while also protecting natural water resources.

Zentrale Forderung: Wasser, das mittels Entsalzung gewonnen wird, muss Minimum für die Bewässerung wieder eingesetzt werden.

KLOTEN-OPFIKON WWTP, Switzerland

High performance using the NEREDA® process for the extension of a municipal WWTP

The existing wastewater treatment plant (WWTP) at Kloten-Opfikon in Switzerland required expansion from 85,000 to 125,000 PE within limited space constraints. Employing the innovative NEREDA® process emerged as the optimal solution. The expansion of the existing plant from 85,000 to 125,000 PE will be achieved without the need for additional space. This space- and cost-saving expansion is facilitated by the utilization of aerobic granulated biomass. This high-performance process can be seamlessly integrated into the existing aeration tanks, requiring only elevation adjustments. The reconstruction of the biological treatment occurs in three stages. NEREDA® Reactors 1 & 2 have already been installed without impacting the ongoing operation of the wastewater treatment plants, and the required effluent parameters have been continuously met.

Explore our innovative technologies for wastewater treatment:

» Fine sieving: MICROPUR®

» Biofiltration: BIOPUR®

» MBBR, Moving bed biology: FLUOPUR®

» Activated sludge processes: HYBRID™, MICROPUR-CAS®

» Aerobic Granular Activated Sludge: NEREDA® (licensee)

» Sequencing Batch Reactor (SBR): CYCLOPUR®

» Membrane bioreactor: MARAPUR®, MICROPUR-MBR®, PACOPUR®-MBR

» Oxidation processes: BIOZONE®

» High-rate clarification: OPUR-SK™

» Adsorption processes: CARBOPUR®, PACOPUR®

» Anammox – Nitrogen removal: DAMOPUR® » Deep bed filtration in various designs